Theme 1 Conquering Low Formability for Optimised Design Architectures

We aim to develop the scientific base required to optimise energy efficient routes for forming advanced light alloy materials to achieve the more complex shapes required by industry for these difficult materials in a cost effective manner. A key ambition is to develop microstructure sensitive models and optimise innovative techniques for extending formability in higher strength, lower ductility, materials and recycled alloys.

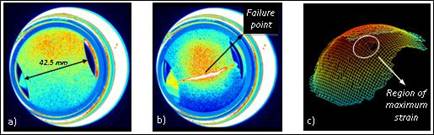

Whereas formability has been extensively investigated in steel and some automotive aluminium alloys, a new approach is required for studying warm deformation in high strength alloys and in hexagonal metals (HCP) e.g. titanium and magnesium. This involves understanding and modelling the development of precipitate distribution and its interaction with deformation during warm forming and then extending the modelling to describe advanced warm forming processes. For titanium and magnesium the aim is to clarify the micromechanics of deformation for implementation in crystal plasticity models that can capture the influences of microstructural and texture heterogeneity that lead to strain localisation and limit formability.

| Another important component of the work in Theme 1 is the control of microstructure during thermomechanical processing, which is essential for good formability. There is particular focus on the role of particles in recrystallization of aluminium alloys, which is increasingly important as recycled content increases, and on the texture homogeneity of titanium and the control of texture and grain size in wrought magnesium alloys. There is also a growing activity on microstructural control of additive manufactured titanium material. |  |

The research is aimed at developing the fundamental science required to underpin the following application areas:

- Developing models for microstructural evolution, including texture, during themomechanical processing of light alloys

- Extending shape capabilities in conventional cold forming of medium strength aluminium alloys with increased recycled content

- Selection and optimisation of new warm forming operations for high strength aluminium alloys

- Energy efficient, warm forming of HCP materials (magnesium, titanium)

- Forming more economic roll cast and recycled materials

Examples of Current Projects

- Control of Twinning in Magnesium Alloys Using Precipitates

- Developing Titanium Alloys with Higher Strength and Improved Ductility

- Improving the Quality of Magnesium Castings using Modelling and 3-Dimensional Imaging

- Investigating the Effect of Particle Shape and Distribution on Recrystallization and Texture in Aluminium Alloys

- The Effect of Temperature on the Formability of High Strength Aluminium Alloys